- Home

- Utilities And Accessories

Utilities And Accessories

UTILITIES AND ACCESSORIES

Suitable to collect, store, heat and blend products like pulp, juice, beverages, sugar syrup and dairy products. These tanks can be fitted with stirrer/blending device and can be manufactured in single/double/triple jacketed designs.

Available in capacities from 100 to 5000 ltr in single/double/triple jacketed models.

Suitable for storage of finished product before filing and packing to ensure free flow of liquids/pulp to the filler by

gravity.

Available in capacity range of 200-1000 ltrs in single/double jacketed/insulated design options with/without stirrer.

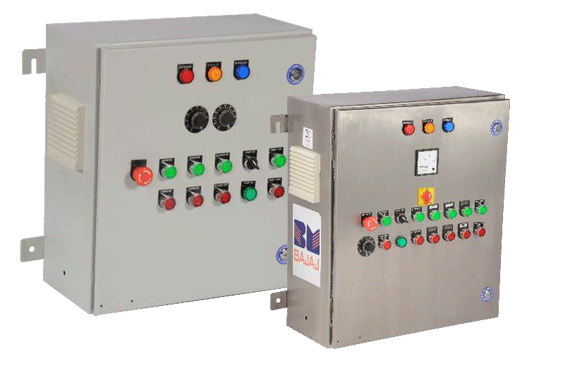

Motor control Panel (MCC) are designed to energise and control all motors mounted on various equipment. Enables single point control of all equipment installed and enhances safety of workers by reducing chances of short circuit/electrocution in a wet working environment.

Available in MS/SS body and is fitted with electrical component/PLC/VFD of international brands and can be designed to conform to IP 44/54/55/ 65 standard.

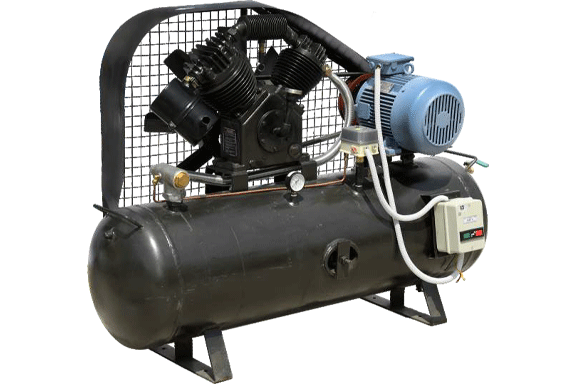

Suitable to produce compressed air needed to actuate pneumatic components fitted on machines.

Available in single/two stage reciprocating models from 4 -80 CFM with inbuilt air storage tank reservoir in low/high pressure models.

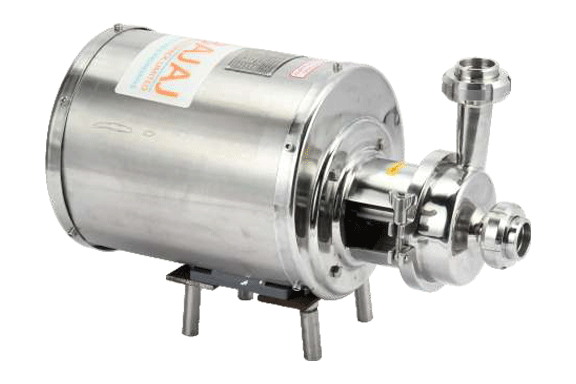

Suitable to transfer free flowing liquids like Juice, water, sugar syrup etc.

Available in capacity range from 200-2000 Lph in SS 304/316 models.

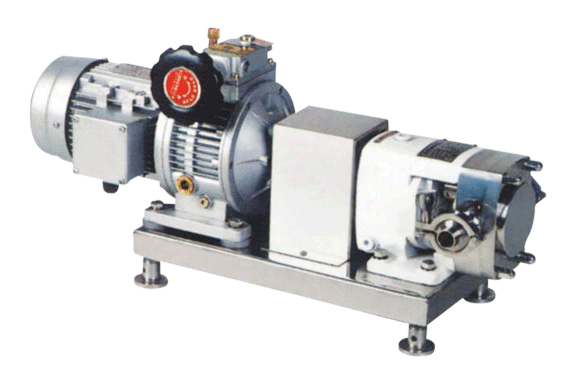

Suitable to transfer viscous

and sticky material like Mayonnaise, cheese spread, salsa, liquids with pieces etc for complete sanitary/CIP conditions and usage.

Available from capacity range of 500-2000 Lph in SS 304/316 models.

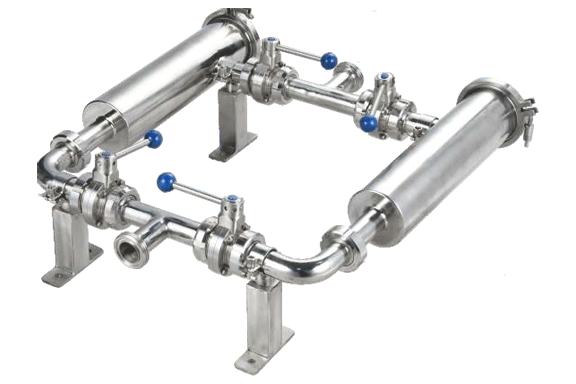

Suitable to filter any foreign particle, impurity from the liquid product being transferred through

pipelines and pump.

Available in single/duplex models to suit capacity range from 200- 2000 Lph.

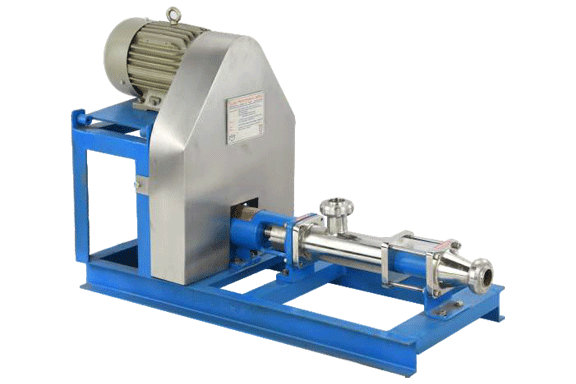

Suitable to transfer thick, viscous products like ketchup, pulp, puree etc.

Incorporates food grade stator/ rotor of SS 304/316 with capacity range from 200-2000 Lph.

Suitable to heat and circulate process water as required in various equipment for heating/boiling/sterilisation.

Available in various capacities from 100-500 kg/hr models, duly fitted with recirculation pump and interconnecting pipelines.

Suitable to circulate process water to maintain the temperature.

Available in various capacities from 5-100 TR models, duly fitted with

recirculation pump and interconnecting pipelines.

Suitable for production of steam used in processing

equipment.

COIL TYPE, REVERSE FLUE MODEL (Non-IBR model)

Available in horizontal/vertical design from 100-800 kg/hr steam output capacity.

Maximum working pressure: 10.5 kg/cm²

Steam Temperature: 185°C

Fuel: Light oil/diesel/wood/coal

HORIZONTAL STEAM BOILER (IBR model)

(3 pass smoke tube type)

Capacity range 500 kg/hr – 2 MT/hr

Fuel: Solid fuel like coal, wood, briquetted agro-waste, husk, LDO/gas

CIP Systems are used for thorough cleaning of various equipment or pipelines installed in dairy, food or beverage industries. The system greatly reduces microbial growth in the processed product and enhances product quality. CIP system includes equipment, pipeline, flow sequence control, heating section, high pressure pump, steam control status and panel.

Available in 1/2/3 tank models to suit plant capacity between 500-2000 kg/hr.