- Home

- Can filling/seaming & packaging/sterilisation/ cooling equipment

Can filling/seaming & packaging/sterilisation/ cooling equipment

CAN FILLING/SEAMING & PACKAGING/STERILISATION/ COOLING EQUIPMENT

DOUBLE SEAMER BM 102-DS

(Can still type)

Suitable for seaming sugar syrup based products like

rasgulla/gulabjamun in cans.

Available in capacities from 20-25 cans/min.

EXHAUST BOX

Suitable to ensure filling temperature >85 °c and exhaust air entrapped in syrup before seaming to increase shelf life.

Available in 12/18 feet model (MS/SS).

SEAMER SS MODEL

Suitable for seaming dry products in cans like namkeen/dry fruits in tin/PET/composite cans with/without Nitrogen flushing.

Available in capacities from 10-15 cans/min.

COOLING CONVEYOR (FOR CANS, BOTTLES AND POUCHES)

Suitable for cooling of hot filled cans/bottles after sealing to create vacuum for long shelf life.

Available in capacity from 1000-6000 cans/bottles per hour

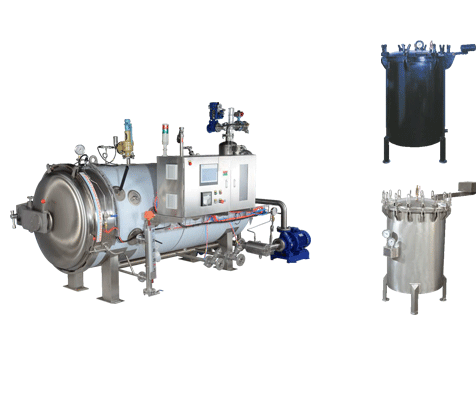

RETORT STERILISER

Suitable for sterilization of cans and glass bottles after exhausting and sealing. Cans 0 or bottles are sterilized up to 110 – 120 C for a period of 15 to 45 minutes as per process requirement.

Available in following models: Vertical (Water immersion) Retort: Available in 21, 90, 200, 300, 425, 600 cans per batch capacities in MS/SS. Automatic Horizontal Counter Pressure Retort: Automatic counter pressure retort has in-built PLC to control sterilisation temperature, time, pressure and cooling process suitable to sterilise can/PP bottles/glass bottles/retortable pouches. Available in 300, 600, 1000, 1500 and 2000 cans/bottles per batch capacities.