- Home

- Homogenizer & Pasteurizer

Homogenizer & Pasteurizer

HOMOGENIZER / PASTEURIZER

Suitable to homogenize juices, pulps, ketchups or milk to desired consistency. The homogeniser is of rugged design with stainless steel cabinet. The homogenizer chamber is made of single piece forged AISI 316 block, suction / discharge valves of stelite and fitted with diaphragm type pressure gauge.

Available in different pressure range models from 20-60 Mpa and capacities from 100-2000 LPH.

Suitable for preheating of pulp extracted for final processing / pulping.

The pulp is circulated through the heat exchanger for preheating up to required temperature. Steam is the heating media used in the heat exchanger to heat the pulp. After achieving the required temperature the product is discharged to a pulper for pulp extraction.

Advantages of Pulp Preheater:

• Deactivating the enzymes, which are likely to be generated.

• Getting good colour and maximum recovery.

• Better quality of the product.

Available in capacities from 500 kg/hr to 2000 kg/hr

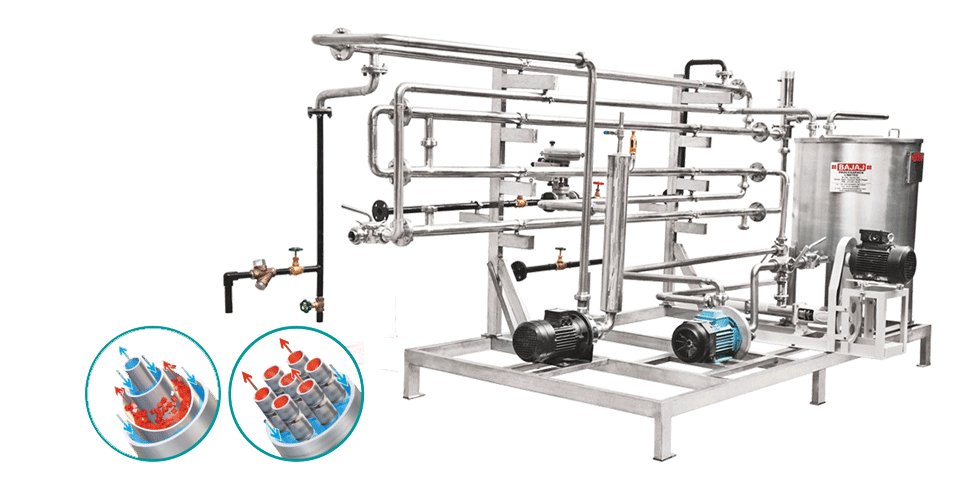

Multi-tube Coaxial Heat Pasteurizer is suitable for continuous pasteurization of products having medium to high viscosity of various fruits and vegetable pulp or puree.

It can be designed as monotube, multitube, shell & tube type models depending on the requirements of the product or capacity required.

Available from 100-2000 kg/hr capacity models