- Home

- Biomass / Solar Powered Cold Stores For Fresh Fruits And Vegetable

Biomass / Solar Powered Cold Stores For Fresh Fruits And Vegetable

Biomass / Solar Powered Cold Stores For Fresh Fruits And Vegetable

Post harvest food loss - A Global challenge

- A majority of post harvest losses of fresh farm produce occur due to lack of farm level cold storage leading to large scale farm losses or distress selling.

- The conventional cold stores can’t be installed at the farms in the growing areas due to unavailability of 3 phase power connection load and its last mile connectivity.

- Most of the large capacity cold stores are located in tier 1 – 2 cities and are often dependent on unreliable 3 phase electrical grid connections which

necessitates diesel generation sets as backup alternative energy source. - The high electrical load cost and high operating cost for 24/7 backup of the diesel generators in cold stores make the storage cost high and is unviable.

To overcome the challenge, Bajaj Processpack Limited offers new-generation cold rooms powered by biomass and solar powered (off grid) that can designed to operate on biomass or solar power, which are not dependent on 3 phase grid power and are easy to operate at very low running cost .

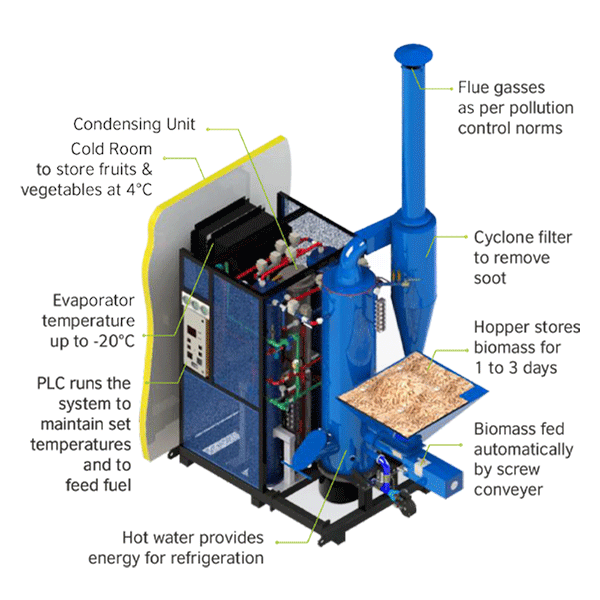

Biomass Powered Cold Room

- Off-grid and compressor-less refrigeration unit Zero GHG emission: Zero ODP (Ozon Depletion Potential) & Zero GWP (Global Warming Potential) using R717 refrigerant

Available from 10 – 40 MT capacity

• Temperature Range: +2° to +25° C

• Humidity Range: 65% – 95%

• Cold Storage: Fruits, Vegetables, Flowers and other perishable storage

• Ripening Chamber for fruits

Suitable for Multiple Applications like Fruits, Milk, Flower, vegetables etc with variable temperature range, suitable to be used as Pre cooling, ripening chamber, Cold Storage and Natural dehydrator.

Condensing Unit Specifications

| Parameter | GreenCOOL-33 | GreenCOOL-42 |

|---|---|---|

| Cooling Capacity at 0°C Evaporator, 25°C WBT | 4 TR (14 kW) | 20 TR (70 kW) |

| Temperatures | Evaporator temperature can be set by user : -20°C to +20°C | |

| Biomass consumption (3500 kcal/kg) | 8kg/Hr(Average 100kg/day)^1 | 40kg/Hr(Average 500kg/day)^1 |

| Energy source | Any loose biomass (straw), pellets or briquettes, steam, waste heat or biogas can be used. Biomass of size 10 to 25 mm can be fed automatically from the hopper. Moisture up to 15% | |

| Electricity Consumption | 0.5 ᵏᵂ²3 , Single phase | 2 ᵏᵂ³ , Single phase |

| Installed footprint | 10 x 5 ft space | 10 x 15 ft space |

| Grid power savings | 70,000 KW-Hr/yea ⁴ | 25,000 KW-Hr/yeaR ⁴ |

| Carbon emission savings | 60 tons/year ⁴ | 200 tons/year ⁴ |

| Carbon emission savings due to zero GWP refrigerant | 2.1 tons/year ⁴ | 100 tons/year ⁴ |

- Depends on daily loading conditions

- Danfoss condensing unit OP-MCZC171MTA consumes 8.5 kW

- Danfoss compressor VHZ170 + condensing unit consumes 30kW

- Assuming 24/7 operation and 0.95 kg Carbon/kW-hr

- 1 kg R404A=4470 kg Carbon. Assume 0.125 kg/TR-year released into atmosphere

Condensing Unit Applications

| Application | Remarks |

|---|---|

| Cold Room | Typically, 20 MT (20x12x9 ft) capacity rooms with modular evaporator unit pre-installed |

| Milk Chiller | Up to 2000 litre BMCs can be integrated to chill milk as per ISO standards |

| Ice blocks | 1 Ton/day. A standard Ice block making machine can be connected to the GreenCOOL condensing unit to chill brine to -10°C to make ice blocks |

| Ripening chamber | Ripening of banana, mango etc |

| Retrofit | GreenCOOL can be installed with existing electrically powered units. GreenCOOL can takeover the main cooling load saving running cost |

Biomass fuel sources: Industrial Waste Heat, Rice, Mustard, Cotton, Wheat Husk (10-30 mm), Biomass Pallets or Crushed Briquettes, Brewer’s Spent Grain, Winery Waste, Grape Seeds, Grape Orchard Waste, Corn Cob, Coconut Shells, Wooden Logs, Dried Cowdung / Goat Dung cake, Poultry Waste, Sugarcane Bagasse, Cashew, Almond, Groundnut, Tamarind, Spent Coffee Ground.

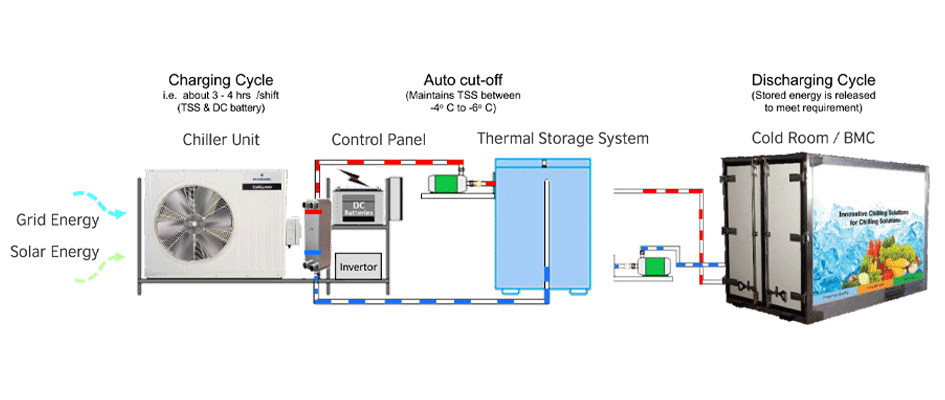

COLD STORES - SOLAR POWERED HYBRID ICE STORAGE TECHNOLOGY

BAJAJ PROCESSPACK LIMITED also offers cold stores with solar powered cold store units with inbuilt thermal energy storage units to provide fast and steady cooling efficiency and short pre

cooling duration. The unique cooling technology offered integrates solar photovoltaic cells with solar powered compressors and the thermal energy storage for an efficient

cooling application.

This technology bypasses the need of grid or expensive electric batteries and incorporates thermal energy units to store energy in low-cost, reliable and environmentally friendly phase change.

These units have no moving parts or chemicals reactions and are housed in Stainless steel construction for a long life.

• Offers a steady temperature range between 4-15 C based on thermal energy storage.

• The solar energy is stored in thermal energy storage units for providing cooling during non-solar hours.

• The system can switch to grid electricity as a backup in case of low thermal energy levels.

• Can be designed and offered for capacities ranging between 5-20 MT cold store capacity.

• Can be designed as independent units or integrated container design for quick site deployment.

| Description | 10 MT | 20 MT |

|---|---|---|

| Internal storage volume | 1500 cubic feet | 3000 cubic feet |

| Temperature range | 4 to 15 C or 0 to 8 C | 4 to 15 C or 0 to 8 C |

| Cooling backup capacity | 200 MJ | 300 MJ |

| Compressor | 2 TR | 3 TR |

| Solar photovoltaic panels | 6 KWp | 10 kWp |

| Multiple chamber options | 1 & 2 | |