- Home

- Homogenisation And Pasteurisation

Homogenisation And Pasteurisation

Homogenisation And Pasteurisation

Different beverages like Mango juice, Apple juice , Mixed , Pineapple & Orange juice and other fruit juice , Synthetic Beverages, Flavoured Milk, Carbonated Beverages, Energy Drinks amongst others require precision engineering for processing and packing a perfect beverage. Everything from sugar syrup preparation, juice blending, Homogenizers, Pasteurizersup to sealing and packing machine that include Blow moulding machine ,Bottle filling machines ,bottle sealing machines, Bottle labelling machines for shrink and BOPP labelling and shrink wrapping machines.These Plants can be set up with capacities ranging from 500 Litres/Hr up to 10,000 Litres/hr on turnkey basis from processing up to end packaging.

Homogenisation

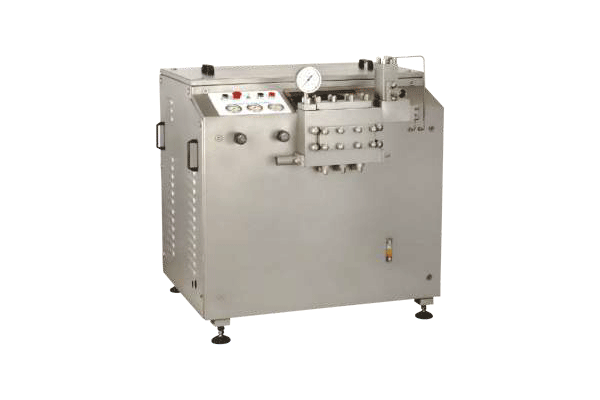

Homogenisation:– Homogenisation are suitable for reducing particle sizes of mutually non-soluble liquids to form a uniform and consistent liquids or beverage. The process involves pumping the blended juice, milk or other liquids through a series of homogenizing valves and pump which breaks down the particle size of liquid into a consistent particle size. Homogenizers are available in a variety of capacities from 500 to 10,000 LPH and pressure ranges from 20 to 60 mpa.

Pasteurisation

Pasteurisation:- Pasteurisation are suitable to eliminate micro-organisms and pathogens in beverage and liquids and extend the food’s shelf life. Pasteurizers for milk ,juice and other beverages involve heating of the liquid to a set pasteurization temperature, holding the same for a period of time to eliminate micro-organisms and disinfect the products from virus and bacteria and thus increasing shelf life. Pasteurizers are manufactured in different designs including Monotube, Multitube, Shell & Tube type, and Plate Type pasteurizers to suit different products, viscosity and in capacities from 500-10000 litres/hr.