- Home

- Evaporation / Pasteurization / Sterilization Section

Evaporation / Pasteurization / Sterilization Section

EVAPORATION / PASTEURIZATION / STERILIZATION SECTION

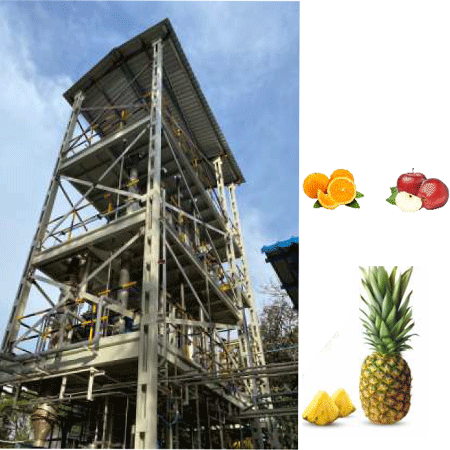

The evaporators / sterilizers / aseptic-fillers are designed / assembled in India / Europe (depending upon capacity) and offered under technical collaboration with leading engineering companies from Europe.

Falling Film Evaporator

Suitable for concentration of all types of clear free flow juices. Available in single / double effect for low to medium capacity plants and triple/quadruple effect with TVR (Thermal Vapour Recompression) on first effect for large capacity plants. Consists of vertical “Falling Film” tubenest, cylindrical evaporator chamber, mixing condenser, vacuum system.

The product to be evaporated flows from top of the evaporator which gets distributed through the film pipes, enabling water evaporation at low temperature.

Available from 2000 to 15000 L/hr water evaporation capacities

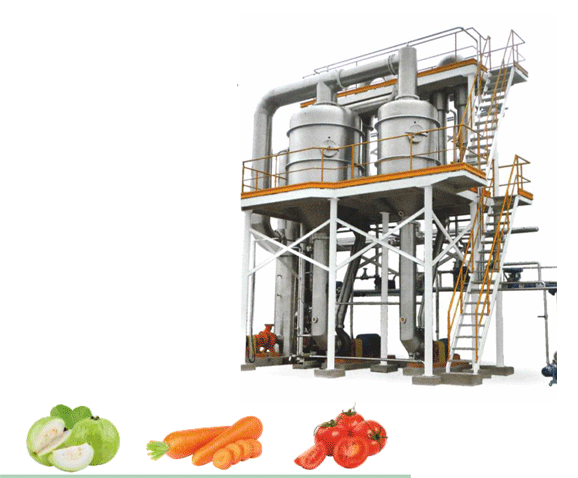

Forced Circulation Evaporator

This is ideal for concentration of high viscous material and products with higher solids like tomato, mango, guava, carrot using the “Hot break” or “Cold break” process. These can also be used in series with a falling film evaporator as a finishing effect for achieving higher concentration. In this type of evaporator, juice / pulp is pumped through heat

exchanger tubes at high velocity thus avoiding precipitation and creating high turbulence. It is then passed through vapor separator for condensing the vapor in the condenser.

Available in capacities ranging from 1500 to 15000 L/hr water evaporation.

Sterilizer

Suitable to sterilize juice / concentrate / puree / paste by thermo physical treatment to reduce bacteria load and ensures long shelf-life.

Can be offered in tube-in-tube, tube nest, scrape surface, plate type models to suit different products.

Available from 1 to 10 MT/hr capacities.